The reel set is an important part of the crane, on which the wire rope is wound, it then controls the lifting or lowering of the load by winding or releasing the wire rope to achieve the work purpose. So, the wire rope as a reel group on the vulnerable parts, wire rope in the reel group on the fixed method is how? The following describes the three commonly used fixing methods.

Steel wire rope in the reel group on the fixed method

Steel wire rope in the reel on the fixed must be very reliable, easy to check and assembly and disassembly, avoid in the fixed place to make the wire rope by excessive bending. At present the commonly used fixing method has the following three kinds:

1, with pressure plate fixed

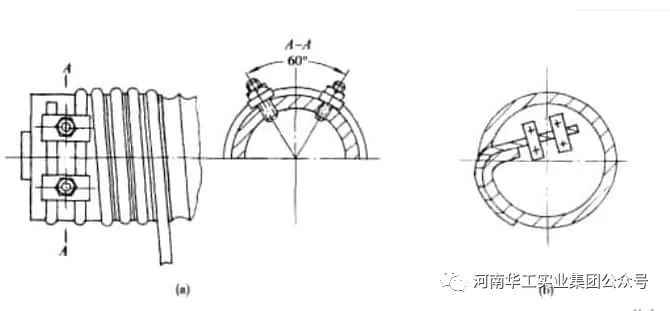

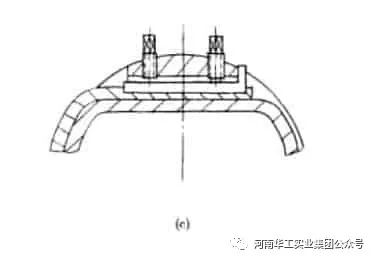

Use pressure plate and bolt in one end of the reel group fixed rope tail, this method (as shown in figure a) construction is simple, easy to install and disassemble, easy to observe and check, reliable, currently more commonly used. When used for multi-layer winding, generally adopt such form as figure b, one end of the wire rope with pressure plate and bolt will rope tail fixed in the flange on the side of the reel group, reduce the occupied space, and facilitate winding.

Steel wire rope in the reel group on the fixed method

Steel wire rope in the reel on the fixed must be very reliable, easy to check and assembly and disassembly, avoid in the fixed place to make the wire rope by excessive bending. At present the commonly used fixing method has the following three kinds:

1, with pressure plate fixed

Use pressure plate and bolt in one end of the reel group fixed rope tail, this method (as shown in figure a) construction is simple, easy to install and disassemble, easy to observe and check, reliable, currently more commonly used. When used for multi-layer winding, generally adopt such form as figure b, one end of the wire rope with pressure plate and bolt will rope tail fixed in the flange on the side of the reel group, reduce the occupied space, and facilitate winding.

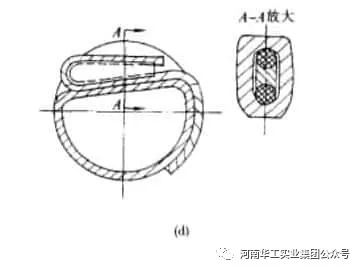

3、 Fixed with wedge

The wire rope is wound on the wedge and fitted into the wedge hole of the reel together with the wedge, and is wedged tightly under the pulling force of the wire rope. The slope of the wedge is generally 1:4~1:5, to meet the self-locking conditions. This method reel construction is complex, not easy to wire rope replacement, but can be used for multi-layer winding.

It should be noted that the wire rope in the reel winding in and out, usually to deflection, its deflection angle can not be too large, otherwise the wire rope will touch the rope groove side or the side of the wire rope and cause wire rope abrasion or rope groove damage, even the phenomenon of jumping groove; light surface reel will make the wire rope can not be uniformly arranged and produce chaotic winding phenomenon.

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat