The crane reel is used to wind the steel wire rope components, in the lifting process, through the reel to collect and release the steel wire rope, drive the pulley set and take the device to achieve lifting load lifting. The material of the reel is preferably cast steel, because the cast steel reel is harder, better wear resistance, strong impact resistance. Next, to explain the crane reel types, structure and use requirements

1) Types of reels

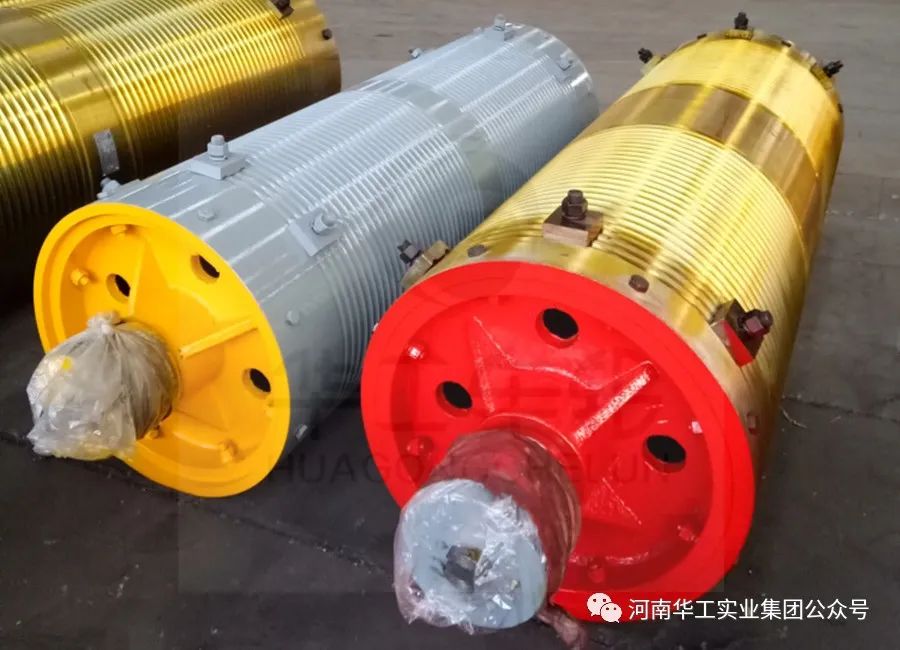

According to the shape of the barrel, can be divided into long axis reel and short axis reel; according to the manufacturing method, can be divided into casting reel and welding reel; according to the surface of the reel barrel whether there is rope groove, can be divided into light surface reel and spiral groove surface reel; according to the rope in the reel winding layer, can be divided into single layer winding reel and multi-layer winding reel.

2) Reel structure

The reel is mainly composed of barrel body, connection plate, reel shaft and bearing support.

3) Safety requirements for reel use

The fixing of the end of the wire rope should be checked once a month. Regardless of the conditions, it must be ensured that the wire rope retains a sufficient number of safety loops on the reel. The end of the barrel of a single winding reel should have a flange, and after the reel has been fully retracted from the wire rope, the height of the end flange surplus should be greater than twice the height of the wire rope to prevent the wire rope from slipping off the end of the reel.

Remind everyone, when the crane reel cracks, cylinder wall wear amount to 20% of the original wall thickness or rope groove wear amount is greater than the diameter of the wire rope 1/4 and can not be repaired, the reel should be scrapped, replace the new reel.

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat